PMT Magnet Drum Separator is ideal for the continuous & automatic removal of iron particles from any dry bulk material. Magnet Drum is "Self Cleaning Separator" as there is no need for manual cleaning.

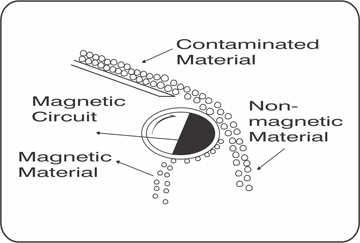

Magnetic Drum is made up of two drums; the inner drum consists of 180 degree magnetic field incorporated withina stainless steel outer drum. The outer drum revolves around the inner stationary drum.For best and effective performance of magnet drum separators, they should be fitted at the discharge end of conveyors, in line with processing chutes orvibratory feeders. Drum consists of key waved shafting to suit the customers drive specifications.

Working :

Material to be processed enters onto to the surface of the drum, the powerful magnetic field attracts the iron particles & the outer drum holds these ferrous particles. When the outer drum revolves & passes off the magnetic field the iron particles falls behind the divider & due to gravity the cleaned material falls separately in the front of the divider. The process material is cleaned automatically & helps in avoiding damages to the machine. The drum rotates at between 20-25 RPM ensuring that even the most heavily contaminated product can be separated. These are very useful in Food Processing, Mining, animal Feeds, Cement, Malt processing & any dry material processing industry. Magnetic Drum Separators are available in different sizes to suit thespecific requirements of customer or applications. We manufacture drum separators with Ferrite composition for standard iron separation and also drum with the "Gemini Rare Earth Powerful Magnet" composition for greater level of iron separation.